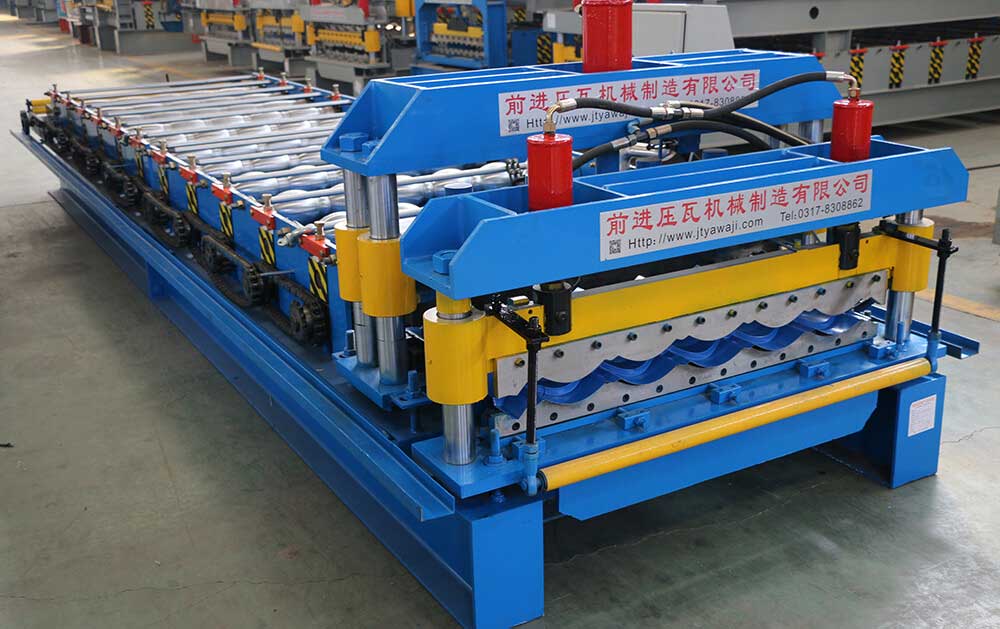

| Under Frame | H-beam |

| Frame Structure | Sidewall 16mm Steel Plate |

| Connect Bar | 25mm Galvanized Steel |

| Screw & Bolt | 8.8 Standard |

| Bearing Type | 6210 Standard |

| Transmission | Gear Box |

| Driving Motor | 7.5KW (Lichao Brand,Shanghai) |

| Voltage Standard | 380V 50HZ 3Phases |

| Forming Roller Station | 11 Steps |

| Forming Rollers Info | High grade 45# Steel ,precision polishing after CNC lathe and then with hard chromed plated 0.05 mm,much more brighter (Key-way method) |

| Forming Roller Shafts Info | High grade 45# Steel ,precision polishing after lathe with Key-way method |

| PLC Control System | Delta PLC , Delta inverter, HIM Screen Operation,Standard lower voltage components, |

| Hydraulic Pump Station | 11KW (Lichao Brand,Shanghai) with Valve (Huade Brand,Beijing) |

| Hydraulic Pressing System | Steel plates welded, guide pillar type for long life cutting, |

| Hydraulic Cutting System | Steel plates welded, guide pillar type for long life cutting, |

| Pressing-Cutting Blade Material | Cr12Mov with heat treatment |

| Cutting Tolerance | 10M±1mm by inverter/PLC control |